B2-coating

B2-coating

B2 is a crosslinked coating that is applied to the surface of elastomeric stoppers. B2 reduces friction on stoppers as they pass through filling lines; this improved lubricity means enhanced stopper machinability.

B2 was developed and patented by Daikyo Seiko and has been used by many pharmaceutical companies for several years. In some instances, manufacturers using B2 coated stoppers have experienced significant increases in line speed. Because the coating process crosslinks silicone oil on the surface of elastomeric closures, the level of subvisible particulate matter may be reduced.

B2-Coating is available at three different levels:

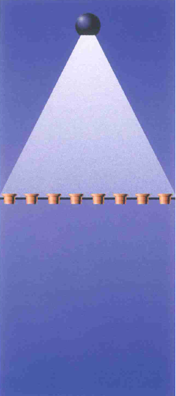

B2-40

- Top surface is coated to the maximum level (level 4)

- Bottom surface is not coated (level 0)

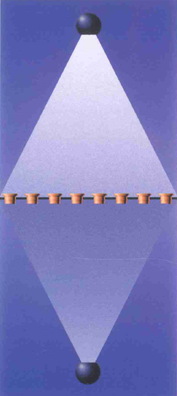

B2-42

- Top surface is coated to the maximum level (level 4)

- Bottom surface is coated to half the maximum level (level 2)

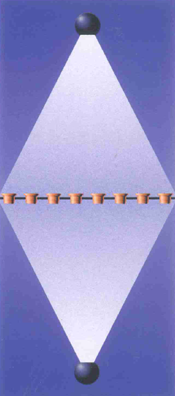

B2-44

- Top surface is coated to the maximum level (level 4)

- Bottom surface is coated to the maximum level (level 4)

B2 benefits

- The B2-process, which crosslinks silicone on the surface of the rubber closures, reduces rejects due to subvisible particulate matter.

- The availability of B2-Coatings at various levels on the bottom and top surface of stoppers makes it possible to achieve the optimum degree of coating, especially for the drug contact side, e.g. no silicone is used at all on the drug contact side of Flurotec products.

- The reproducible amount of fixed silicone crosslinked on the surface ensures machinability of treated rubber stoppers. No further siliconising is required by the customer.

- B2-coating is possible for almost all established rubber products and formulations. This means that high-cost compatibility testing is reduced.

- Combined with STERIlizableBAG and rinsed with WFI, B2-Coating makes preconditioned "ready-to-sterilise" possible in practice and paves the way for future "ready-to-sterilise" products.

B2-coating technology is licensed from Daikyo Seiko, Ltd.