Acceptance Quality Limit (AQL)

The Acceptance Quality Limit (AQL) is a proven statistical instrument at the disposal for quality control when it comes to evaluating product quality.

The need for quality control

In virtually every production batch, there will be defective products - however they could be extremely rare. There will always be defective products even after the QC has checked and repaired each individual product. Flawless products only exist in a perfect world, the goal is to create products that are within acceptable tolerances. Although the quality assurance systems of manufacturers of primary packaging materials are becoming increasingly more efficient through the use of innovative technologies, such as electronics and laser refraction modules, there will always be room for improvement and there are always ways to make it even better; each production run is another opportunity to create new quality standards. Notwithstanding the fact that a buyer always want a zero defect product, the supplier cannot be expected to deliver absolute zero defect goods. However, the buyer wants to control the consistent quality of purchased goods, since it does not want (too many) defects.

AQL background

Not each and every individual product can be fully checked as to its functionality. Products would become highly expensive or even instantly obsolete, as destructive test methods would destroy the product. For this reason acceptance sampling has been developed. Acceptance sampling is a statistical quality control instrument that represents a compromise between doing no inspection and a full inspection. Acceptance sampling originated way back, even before the Second World War, when the US military had to determine which batches of ammunition to accept and which bullets to reject by a destructive test method. The US army therefore developed the Military Standard 105-D, testing a few representative bullets from the production batch so they could trust the other bullets would perform on the battle field. Ultimately this might mean the difference between life and death.

The sampling scheme by which representative samples (sample rate) are selected from a population (production batch/lot) and tested to determine whether a production batch/lot is acceptable or has to be rejected is known as an acceptance plan or sampling plan administrated??? according to DIN ISO 2859 part 1. Hence the AQL, defined as the quality level that is the lowest acceptable, is a statistical procedure for determining production batch/lot quality.

AQL standard for moulded glass

Primary packaging materials made of moulded glass for pharmaceutical and cosmetic purposes are often manufactured according to quality agreements based on the "Defect Evaluation List for Containers Made of Moulded Glass" and to the appropriate GMP Rules of the WHO (see "Editio Cantor" )

Acceptable defect level:

Om het maximum aantal ondeugdelijke eenheden (het acceptabele aantal ondeugdelijke producten) te bepalen, moet een kwaliteitsinspecteur weten:

- The production batch/lot size

- The inspection level

- The random sample size

- The AQL portion

To determine the correct sampling plan and acceptance/rejection level, quality inspectors rely on basically two AQL tables:

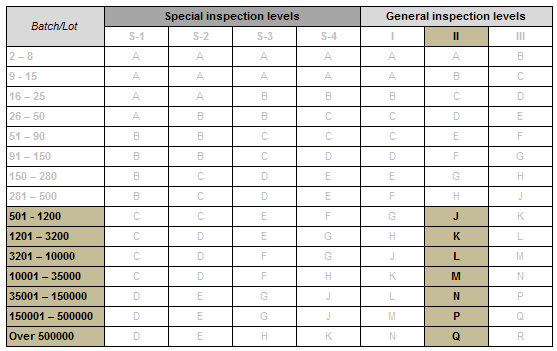

- The first table determines which 'code letter' to use based on the inspection level and production batch/lot size.

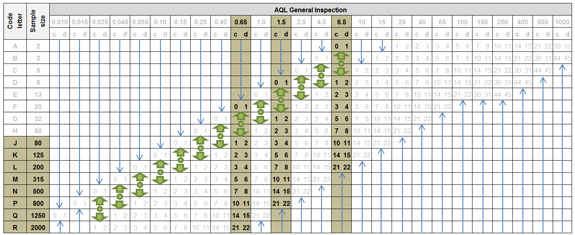

- The second table determines the sample size and maximum number of defects that can be accepted based on the code letter and AQL.

General inspection level II is the most widely acceptable level for moulded glass bottles.

Table 2 -Single sample plans for normal inspection according DIN ISO 2859-1

Classification

The most widely acceptable defect classes and AQL portions for moulded glass:

- Defect class 1, critical defect; Consequently AQL defect portion -

- Consequence: Packaging material not usable

- Defect class 2A, major defect; Consequently AQL defect portion 0.65

- Consequence: Usability of packaging material markedly impaired

- Defect class 2B, major defect; Consequently AQL defect portion 1.5

- Consequence: Usability of packaging material moderately impaired

- Defect class 3, Minor defect; Consequently AQL defect portion 6.5

- Consequence: Usability of packaging material slightly impaired

Defect counting rules:

The number of defects found for each defect class is typically calculated according to the following procedure:

- Each individual defect is counted.

- If one bottle has more than one defect, it is only count once.

- In case multiple defects at one bottle belong to multiple defect classes, the lowest AQL sets the acceptable defect limit.

Example of a defect evaluation

QA have noticed an inside open glass bubble (defect# 14.05.11) in two production batches of 550,000 moulded glass bottles. According to the current defect evaluation list this represent defect class 2A, i.e. an AQL defect portion of 0.65. What would be the correct sample size and the acceptable number of defects?

Counting results for batch 1 (demo)

- The inspection level is determined to be General inspection level 'II'. Consequently, the code letter is "Q". (table 1)

- Consequently the random sample size from the total production batch is 1,250 units. (table 2)

- Defect class 2A, major defect; Consequently an AQL defect portion of 0.65

- Acceptance number of defective bottles is a maximum 14 at an AQL portion of 0.65 (table 2)

- The rejection number of defective bottles is 15 or more at an AQL portion of 0.65 (table 2)

Resultaten van het tellen bij partij 1 (demo)

Quality inspectors found the following numbers of defective bottles:

- 12 bottles with different defect characteristics within defect class 2A

- 10 bottles with different defect characteristics within defect class 2B

- 12 defects at defect class 2A is less than the highest acceptable number of defects (14).

- 10 defects at defect class 2B is less than the highest acceptable number of defects (21 see table 2).

Result: Production batch 1 is release/approved as none of the defect classes (2A and 2B) are met.

Counting results batch 2 (demo)

Quality inspectors found the following number of defective bottles:

- 14 bottles with different defect characteristics within defect class 2A

- 22 bottles with different defect characteristics within defect class 2B

- 14 defects at defect class 2A is equal to the highest acceptable number of defects (14).

- 222 defects at defect class 2B is above the highest acceptable number of defects (21 see table 2).

Result: Production batch 2 is rejected/not approved as one of the defect classes (2A and 2B) is not met.

The above examples, counting rules and AQL portions used are for demonstration purposes only.