Filters and filtration apparatus

DURAN® filters and the corresponding filter plates are precision manufactured from DURAN® borosilicate glass 3.3 with its high chemical and thermal-shock resistance. They are entirely inorganic and inert in most circumstances. There are therefore no leachable organic or ionic species present that could otherwise contaminate the filtrates. They are ideal for separations, e.g. with strong acids or alkalis and can likewise be readily cleaned and reused. DURAN® filter products have a maximum operating temperature of +450 °C.

DURAN® filtration vessels are specially optimised to the matching filtration apparatus (eg funnels with guko adapters) and are vacuum-tight due to their special geometry and high wall thickness. Their designs have been approved by the TÜV accreditation body and marked with the “GS” indication were appropriate; see specific products for details.

DURAN® filtering apparatus

The filter apparatus has virtually universal applications with regard to the chemicals to be filtered because the medium only comes into contact with glass and PTFE. The graduated funnel simplifies dosing and analysis. The tried-and-tested DURAN® filtering flask and PTFE hose connection enable safe working in the laboratory. Thanks to the PTFE plate holder, porous glass plates with different porosities can also be used in addition to the split sieve. Filter paper, membrane filters (47mm) or just glass filters can be used for filtration. The replaceable plates and the PTFE adapter in conjunction with the clamp enable rapid changing of porosities or replacement of filters. Cleaning has been significantly simplified compared to a traditional filter funnel as the filter plate can be cleaned quickly and easily from both sides.

Recommendations

Coarse and fine and also analytical filtration can be carried out thanks to the available porosities of 10µm -160µm. Furthermore, the filtration appliance is also suitable for the filtration of HPLC media, testing for bacterial contamination, residue analysis and the filtration of other media.

Porosity

Porosity measurement is by the Bechhold bubble pressure method, which is widely described in the literature1. In the interests of rapid filtration every effort is made to produce filter disks with as many open pores as possible without blockages or closed cavities. This is one of the areas where DURAN® glass filters stand out.

Prerequisite for the successful use of glass filters is selection of the correct porosity. In this respect, the following table lists details of six porosity ranges with indications of their main areas of application. A point to be borne in mind is that the filtration equipment should ideally be selected to ensure that the nominal size of the largest pore is somewhat smaller than the smallest particles to be filtered out. This will prevent infiltration of particles into of the pores.

For quantitative analysis applications, porosity 3 or porosity 4 glass filtration apparatus is used almost exclusively. Different working methods often contain different porosity indications here for the same materials. This is because different processes used in the production of precipitations for gravimetric analysis often result in different grain sizes.

|

|

|||

| Porosity | New identification ISO 4793 | Nominal max. pore size µm | Areas of application, examples |

|

|

|||

| 0 | P 250 | 160 - 250 | Gas distribution: Gas distribution in liquids with low gas pressure. Filtration of coarsest precipitates. |

| 1 | P 160 | 100 - 160 | Coarse filtration, Filtration of coarsest

precipitates. Gas distribution in liquids Liquid distribution, coarse glass filters, extraction apparatus for coarse-grained material. Substrates for loose filter layers against gelatinous precipitates. |

| 2 | P 100 | 40 - 100 | Preparative fine filtration: Preparative work with crystalline precipitates. Mercury filtration. |

| 3 | P 40 | 16 - 40 | Analytical filtration: Analytical work with medium fine precipitates. Preparative work with fine precipitates. Filtration in cellulose chemistry, fine glass filters. Extraction apparatus for fine grained material. |

| 4 | P 16 | 10 - 16 | Analytical fine filtration: Analytical work with very fine precipitates. (e.g. BaSO4, Cu2O). Preparative work with correspondingly fine precipitates. Non-return valves and check valves for mercury. |

| 5 | P 1,6 | 1,0 - 1,6 | Ultrafine filtration |

Flow rate

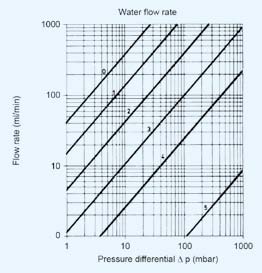

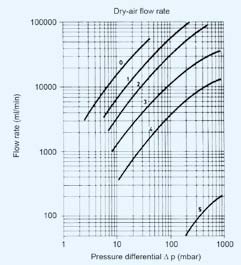

To determine the possible applications of glass filter disks and filtration apparatus, it is necessary to know not only the porosity, but also the flow rates of liquids and gases. These are given in Figures 9 and 10 for water and air. The data applies to 30 mm diameter filter disks.

| Water flow rate | Dry-air flow rate |

|

|

| Water flow rate through filter discs of various porosities as a function of pressure differential. For filter discs with Ø 30 mm | Air flow rate through fi lter discs of various porosities as a function of pressure differential. For filter discs with Ø 30 mm |

The flow rates for other disk diameters can be calculated by multiplying the value read off by the conversion factor given in Table the following table:

| Filter disk diam. (mm) | 10 | 20 | 30 | 40 | 60 | 90 | 120 | 150 | 175 |

|

|

|||||||||

| Conversion factor | 0,13 | 0,55 | 1 | 1,5 | 2,5 | 4,3 | 6,8 | 9,7 | 15 |

Care and cleaning of filtration apparatus

In addition to the information, please also note the following guidelines relating to thermal stresses, which apply specifically to filtration apparatus, in order to avoid glass breakage.

Temperature changes (thermal shock), drying and sterilisation

- The maximum permissible operating temperature is +450 °C.

- Uniform heating is recommended to avoid thermal stresses and resultant breakages.

- Heat glass filtration apparatus with disk diameters of more than 20 mm in initially cold ovens or sterilisers only.

- The heating or cooling rate should not exceed 8°C/min.

- When filtering hot substances avoid temperatures differences of more than 100 K; if necessary, preheat the filtration apparatus in a drying cabinet.

- Wet filtration apparatus should be heated slowly up to 80 °C and dried for one hour before increasing the temperature further.

Whenever possible, filtration apparatus should be stood on its rim (stem upwards) to allow air convection between the inside of the vessel and the oven chamber. If placing the filtration apparatus in the oven at an angle cannot be avoided (as in the case of pipeline filters), any support point close to the position of the filter weld must be protected against heating up prematurely by placing heat-insulating material under it.

Cleaning new glass filtration apparatus

Before using glass filtration apparatus for the first time, it should be rinsed with water (if applicable, acid), to remove any minor contamination that may be present.

Mechanical cleaning

In many cases, if no precipitate has infiltrated the pores, simple spraying of the surface (e.g. with a spray bottle) will suffice. Brushes or rubber wipers can also be used to clean the surface of the filter disk. If some precipitate has infiltrated into the pores, then back-flushing of the disk is required.

Recommendations

- Glass filters should always be cleaned immediately after use.

- Do not use sharp objects to remove the filtrate to prevent damage to the filter surface.

Chemical cleaning

If some of the pores on the filter disk still remain clogged after mechanical cleaning or if it is desirable to make sure that no residue from previous work remains before filtering a new substance, then thorough chemical cleaning is necessary. The choice of solvent used depends on the nature of the contamination (see example in the following overview).

| Borium sulfate | hot conc. sulfuric acid |

| Silver chloride | hot ammonia liquor |

| Red copper oxide | hot hydrochloric acid and potassium chlorate |

| Mercury residue | hot conc. nitric acid |

| Mercury sulfide | hot aqua regia |

| Albumen | hot ammonia liquor or hydrochloric acid |

| Grease, oil | acetone, isopropanol |

| Other organic substances | hot conc. sulfuric acid with addition of nitric acid, sodium nitrate or potassium dichromate |

When chemical cleaning is completed, it should be followed by thorough rinsing with copious amounts of water. Use of hot concentrated phosphoric acid and hot alkali solutions is not recommended, as these may attack the glass surface.

Screwfilters with interchangeable filter disks

With 3 filter sizes, each having 4 filter disks of varying porosity, 12 different filter rates are available. DURAN® screwfilters have a range of benefits compared with conventional filter apparatus:

Interchangeable filter disks

- Safe and simple removal of the filtered material

- Disks have longer service life, as no damage is caused by scraping off the fiItered material

- Filter disks are easy to clean from both sides

- Slit sieve (Cat. No. 21 340 31) can be used in the medium sized screwfilter to support membrane and paper filters

- Space saving

- Cost-effective; filter disks and apparatus can be ordered individually, as required.

Recommendations

The filter disk should be located between 2 FKM gaskets.